Science du bâtiment

Foire aux questions au sujet du retardateur de diffusion de vapeur

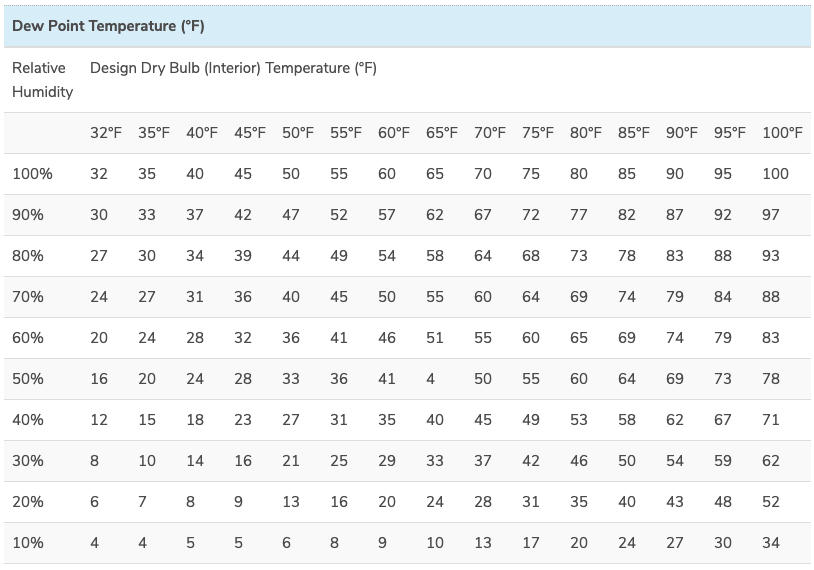

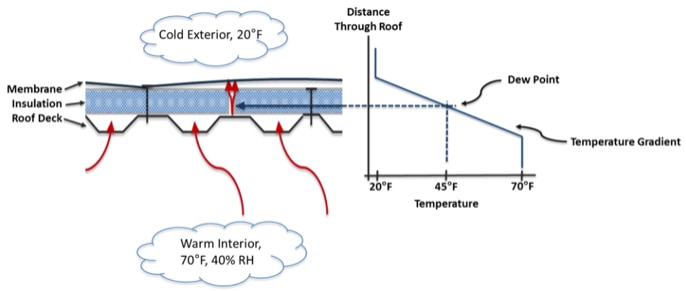

Les retardateurs de vapeur sont de plus en plus souvent préconisés dans les assemblages de toitures à faible pente. Ils peuvent aider à gérer la migration de l'air humide de l'intérieur du bâtiment vers la face inférieure de la membrane du toit. De plus, ils peuvent contribuer à limiter la quantité d'humidité qui migre d'un platelage en béton vers l'assemblage du toit. En fait, nous proposons le Retardateur de diffusion de vapeur GAF SA, un produit en feuille auto-adhésive, pour aider à réduire ce risque. If you are designing a new roof and want to reduce possible moisture risks or are replacing a roof assembly where there's evidence of moisture issues, this article may help you to understand more about the use of vapor retarders.In addition to this article, we also have a Guide to Vapor Retarder Design in Low-slope Roof Systems which describes best installation practices. Ce guide et cet article visent à aborder les principes de base des retardateurs de diffusion de vapeur à l’intention des concepteurs qui souhaitent s’attaquer à la migration de l’humidité. Later articles will cover more fundamental considerations.The answers to these frequently asked questions may sometimes repeat key information, and the reader can jump to those questions of most interest. But reading all of the answers will help get a better overall understanding of the function and role of vapor retarders.What is a vapor retarder?It is a material that, depending on its exact specification and correct installation, blocks or slows down the transmission of moisture from one side to the other. Vapor retarders can be coatings, boards with taped joints, or membranes.Looking at this schematic, it is clear that in an actual roof assembly any penetrations have to be sealed otherwise the vapor retarder's function is degraded - more on this later.How does a vapor retarder function?A properly installed vapor retarder at the deck level can help slow down or block the movement of moisture from the building's interior migrating up into the roof roof assembly. Blocking or slowing down the movement of moisture can be part of an effort to lower condensation risks within the roof system during cold winter months.Vapor retarders can also have some degree of moisture permeability. Les retardateurs de diffusion de vapeur peuvent se composer de matériaux de différentes catégories (I, II et III), dont chacune permet à différentes quantités de vapeur d’eau de pénétrer par diffusion. La possibilité de limiter la diffusion de la vapeur tout en laissant circuler en partie la vapeur d’eau à travers le matériau peut être cruciale, car cela évite d’emprisonner l’humidité à l’intérieur de la toiture. Roof membranes are moisture impermeable, so if moisture does get into the assembly, a properly specified vapor retarder with some degree of moisture permeability can allow the moisture to slowly escape downwards.How does a vapor retarder differ from an air barrier?To state the obvious, properly installed air barriers block air, and as a result will also block the movement of humid air, thereby retarding or stopping most moisture movement. Les pare-air et les pare-vapeur sont parfois en apparence très semblables, voire identiques. Cependant, les utilisations des uns et des autres sont en général différentes. For more on this, check out this article.A good roof membrane, such as GAF EverGuard TPO will not only block air and moisture but also withstand ordinary wear and tear.A good vapor retarder, such as GAF SA Vapor Retarder, is normally used within a roof assembly to reduce moisture movement. Sa perméabilité est faible, voire nulle, car il a pour fonction principale de limiter la circulation de l’humidité. While it can act as a temporary roof, it is not intended to be wear- and tear-resistant in the same way as a roof membrane.Is a vapor retarder required?Building codes do not require the installation of a vapor retarder in roof assemblies. La décision d’en inclure ou non doit être prise par un concepteur professionnel. D’autres réponses que vous trouverez dans cet article peuvent vous aider à définir les facteurs à prendre en compte pour une telle décision, mais un concepteur professionnel doit prendre l'ultime décision selon les caractéristiques propres à un projet. Basically, a vapor retarder can be specified and correctly detailed in order to manage the migration of moisture vapor to prevent wetting and enable drying within a roof assembly.Does vapor retarder use depend on a building's location?The location has a significant impact on the decision to incorporate a vapor retarder into a roof assembly. Le concepteur du bâtiment doit tenir compte de la direction principale de la circulation de l’humidité à l’intérieur de l’enveloppe du bâtiment. Keep in mind that moisture drive is normally from warm (high vapor pressure) to cold (low vapor pressure).If the building is located in the north, moisture drive is the strongest in the winter. La température est généralement plus élevée à l’intérieur du bâtiment qu’à l’extérieur. Tout air humide intérieur qui entre en contact avec les couches externes de l’enveloppe peut entraîner de la condensation en raison des températures inférieures à l’extérieur. In a roof assembly, a vapor retarder located towards the bottom side of the roof assembly can help reduce or throttle back the migration of water vapor from the interior warm side to the exterior cold top of the roof assembly.For a normal building occupancy and where the building is located in a consistently humid climate, the moisture drive is predominantly towards the interior of the building. Dans une telle situation, l’air chaud et humide qui se trouve à l’extérieur peut entraîner la formation de condensation s’il traverse l’enveloppe du bâtiment et entre en contact avec les surfaces intérieures plus froides. Roof membranes are inherently vapor retarders so downward or inward vapor drive is blocked.For buildings with high occupant moisture generation, or that are located somewhere with a mixed vapor drive depending on the season, the roof designer should consider the appropriate roof assembly for the application. If moisture drive from the interior up into the roof assembly could lead to condensation within the roof assembly, then a vapor retarder should be considered.Isn't the roof membrane a vapor retarder? Why do I need another one?Roof membranes are generally vapor impermeable, but to be considered as vapor retarders one has to consider their use. Dans les bâtiments des régions nordiques où la vapeur circule vers le haut à travers la toiture, la membrane sert de barrière contre les intempéries extérieures. Elle peut également faire office de pare-air en empêchant l’air conditionné intérieur de s’échapper, mais elle n’empêche pas l’air humide intérieur de monter à travers la toiture. If water vapor is able to migrate upwards towards the roof membrane, then there can be a condensation risk depending on factors such as the exterior temperature and the interior humidity level.Where should a vapor retarder be placed within a roof assembly?The simplest answer to this question is as close to the interior conditioned space as is practically possible. Cependant, vérifiez toujours que le code local de prévention des incendies autorise l’application des membranes autoadhésives directement sur les platelages en acier. Sur un platelage en acier, il est souvent nécessaire d’installer d’abord un panneau de gypse ou de matériau cimentaire qui servira ensuite de substrat sur lequel on colle le retardateur de diffusion de vapeur. Always check with the roof system designer to make sure that a proposed system meets all necessary codes.Alternatively, the vapor retarder could be applied to the topside of the first layer of insulation, but in such a case, the designer would need to confirm that the dew point would be above the vapor retarder.Can I use black poly (e.g. Visqueen) as a vapor retarder?Black poly sheet, technically 6 mil polyethylene, is often used as a vapor retarder in residential crawl spaces. However, its use in roof systems is generally not recommended for several reasons:It does not self-seal around fasteners that penetrate through it. Vapor retarders such as GAF SA Vapor Retarder are designed to meet a self-seal test described in ASTM D1970.Polyethylene is notoriously difficult to adhere to, which makes flashing and sealing around penetrations very difficult and unlikely to be durable.6 mil polyethylene is essentially impermeable, which means that any leak in the roof covering will let in water that can't escape. De plus, si de l’eau était présente lors de l’achèvement de la toiture, par exemple en raison de la rosée ou d’une légère averse au cours de la nuit précédente, elle ne pourra pas s’échapper. Les retardateurs de diffusion de vapeur dotés des bonnes caractéristiques sont partiellement perméables et ils permettront à l’eau qui se trouve dans la toiture de se déplacer vers le bas. The only exception to this may be for a building with a very high interior humidity when it might be advisable to have a vapor retarder with essentially no permeabilityMy building is in the north, so do I automatically need a vapor retarder?No, a roof designer needs to evaluate the risk of condensation occurring. L’utilisation du bâtiment, le type de bâtiment et la conception de la toiture sont d’importants facteurs à prendre en compte. An evaluation of condensation risk asks questions including:What is the humidity level likely to be in the building? Office buildings can be expected to have lower levels versus buildings with restaurants or indoor pools.If activities within the building could generate high humidity levels, has the HVAC system been designed to reduce the levels with make-up air?What is the building's location and what are the coldest exterior temperatures that could be expected?Will the roof assembly inhibit air flow without the use of a vapor retarder? Some roof assemblies, particularly those that have adhered layers, are more restrictive of air flow than others.Once interior humidity levels have been estimated and outdoor cold temperatures known, then the building designer can calculate where the dew point will be in the roof assembly. If the designer specifies a vapor retarder, it should always be located below the dew point.How should a vapor retarder be tied in, flashed to penetrations, etc?To be successful, penetrations through the vapor retarder need to be flashed and air tight. De plus, les rebords doivent rejoindre les murs. Il faut faire attention à ce que l’air intérieur ne puisse pas facilement contourner le retardateur de diffusion de vapeur et s’infiltrer dans la toiture ou un mur de parapet. The GAF Guide to Vapor Retarder Design in Low-slope Roof Systems provides system details to help guide good design.Should a vapor retarder be used with a concrete deck?In new construction, it can be difficult to ascertain when concrete decks are sufficiently dry to allow the roof assembly to be installed. If significant levels of moisture are present in the concrete deck after the roof is closed up, then problems can arise.For more on the topic of moisture in concrete roof decks see this article by my colleague James Kirby. Briefly, as advised by industry groups such as the Midwest Roofing Contractors Association (MRCA), the use of a vapor retarder over a concrete deck will limit moisture passing through to the roof assembly.In re-roofing situations over concrete decks, there is usually less concern about moisture being present within the concrete deck, providing that there have been no leaks. Toutefois, si le toit d’origine a été installé avec une isolation minimale, le béton risque de contenir d’importantes quantités d’humidité en raison de la condensation, selon le climat local. De plus, toute précipitation pendant les travaux de réfection de la toiture pourrait permettre à un platelage en béton d’absorber de l’eau. If there is any concern about moisture in an existing concrete deck, a vapor retarder should be considered.In new construction, is there a concern about moisture from a concrete floor or foundation?Yes, there can be, depending on location and other factors. Dans certaines constructions à grande surface où la toiture du bâtiment a été achevée rapidement après le coulage d’une dalle de plancher, des problèmes de condensation sont survenus au cours de la première année d’occupation. Cela est lié à un taux d’humidité élevé à l’intérieur, car le béton met des mois à sécher pendant et après la construction. Concrete floors and foundations can take a long time to dry and as a result interior moisture levels can be high enough that condensation has been known to occur in climate zones 3 and 4.Building designers and architects of such buildings often include a vapor retarder in the roof assembly in order to reduce condensation risks during construction, after the building is closed up, and for up to 12 months later.What about where the vapor retarder meets the edge of the roof?Sealing and termination of vapor retarders around the perimeter is difficult. Les concepteurs de bâtiments doivent comprendre qu’un retardateur de diffusion de vapeur a pour but d’empêcher l’air intérieur humide de remonter vers l’intérieur de la toiture tout en permettant une certaine perméabilité contrôlée à la vapeur afin que l’humidité qui pénètre dans la toiture puisse redescendre vers l’intérieur du bâtiment. The GAF Guide to Vapor Retarder Design in Low-slope Roof Systems provides edge termination details to help guide good design.I often see dew point and vapor retarders being discussed together. Why?It's important to make sure that a vapor retarder is installed below where the dew point in the roof assembly is calculated to be. Le retardateur de diffusion de vapeur réduira ainsi le risque que l’humidité n’atteigne cet endroit et ne forme de la condensation par temps froid. Calculation of the dew point takes into account the expected interior humidity levels and the possible exterior temperatures.What is condensation risk and should I always include a vapor retarder?Moisture is well known to lead to problems with respect to the durability of a building enclosure. Le risque de condensation à l’intérieur d’une toiture doit être évalué par un concepteur professionnel. Cette analyse doit prendre en compte divers facteurs, notamment l’utilisation qui est faite du bâtiment et le climat. It is important to recognize that there often is not a definitive yes/no answer to the question as to whether a vapor retarder is needed.The colder the climate, the higher the risk of condensation within the roof assembly. So, buildings located in northerly regions will generally have a higher risk of condensation forming in the building enclosure.The higher the anticipated interior moisture load, the higher the risk. Les immeubles de bureaux qui ne sont occupés que pendant la journée présentent un risque moindre comparativement à un bâtiment abritant une piscine. A building closed up during construction while a concrete slab floor is still drying will likely have a higher risk.The roof assembly design is also a factor. Les vents violents peuvent faire gonfler les membranes monocouches fixées mécaniquement, ce qui cause l’entraînement d’air dans la toiture et qui peut accroître le risque de condensation. Pour minimiser le risque de condensation, les concepteurs de toiture doivent d’abord envisager de contrecoller la membrane et la couche supérieure d’isolant, ce qui rend plus difficile l’entraînement d’air et d’humidité à l’intérieur de la toiture. If a cover board is being used, it should also be adhered.ConclusionsVapor retarders can be used to reduce the movement of vapor within a roof assembly. Ils doivent être placés aussi bas que possible dans la toiture et toute perforation doit être scellée de façon étanche. Vapor retarders in the roof assembly may be beneficial in buildings with large temperature differences from interior to exterior throughout the year, and occupancies with higher than normal interior moisture levels, either from use or during construction.Important ConsiderationsThe purpose of this article is to provide some background information and design considerations for roofing assemblies using vapor retarders. GAF fabrique et vend des matériaux de couverture, mais n’est pas responsable de la conception ni de la construction des bâtiments. La responsabilité de la conception incombe à l’architecte, à l’ingénieur, à l’entrepreneur en pose de couvertures ou au propriétaire. Ces renseignements ne doivent pas être considérés comme exhaustifs et ils ne remplacent pas non plus les bonnes pratiques. Veuillez consulter votre professionnel en conception pour obtenir de plus amples renseignements.

By Authors Thomas J Taylor

01 juin 2021