Les bâtiments sont conçus pour que les conditions météorologiques restent à l'extérieur et que l'espace intérieur soit adapté aux besoins de ses occupants. L'enveloppe d'un bâtiment est constituée de plusieurs couches de matériaux dont le but est d'arrêter les déplacements d'eau, d'air, de chaleur et de vapeur incontrôlés.

On roofs, these layers must include an air barrier and sometimes a dedicated vapor retarder. When designed and installed properly, they can help building owners save energy while maintaining occupant comfort. Voici les éléments-clés à comprendre.

Understanding the Importance of Air Barriers

Uncontrolled air movement is a problem for two reasons: energy loss and moisture. According to BuildingGreen, uncontrolled air movement accounts for 10 % to 40 % of heat gain or loss in buildings. This loss means additional energy must be used to maintain a constant interior temperature. To reduce this unnecessary energy usage, the International Energy Conservation Code (IECC) now requires continuous air barriers on all six sides of a building.

Air also brings uncontrolled moisture vapor into building assemblies. One hundred times more moisture will come through one square-inch hole by way of air infiltration than will come through a 4-by-8-foot piece of gypsum by way of diffusion during the same time period. So, it's critical to ensure buildings are properly sealed for air infiltration.

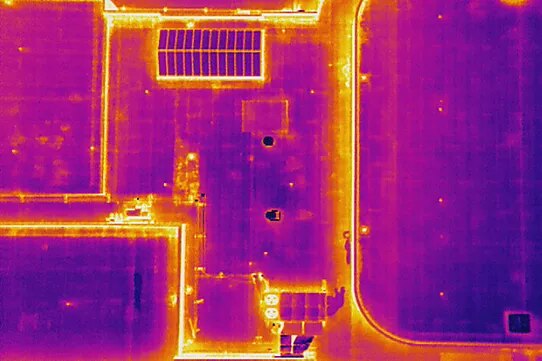

When it comes to air barriers, proper installation is more critical than the material used. They should be installed as part of an air barrier assembly, not just as an added layer on the roof or exterior walls. If the air barrier on the roof isn't properly tied into the air barrier assembly on the walls, interior air could escape around the roof perimeter. This can be seen as heat loss in the yellow and white colors in an infrared photo.

Figure 1. IR Camera image of building roof looking down, showing temperature difference at roof perimeter, indicating air loss (Image courtesy of Nexus).

Designing the Air Barrier Assembly

In most roof assemblies, the roof membrane is the primary air barrier. Its effectiveness in providing a continuous air barrier-based on how the layers of the assembly are attached and if a vapor retarder is installed-depends on the rest of the assembly.

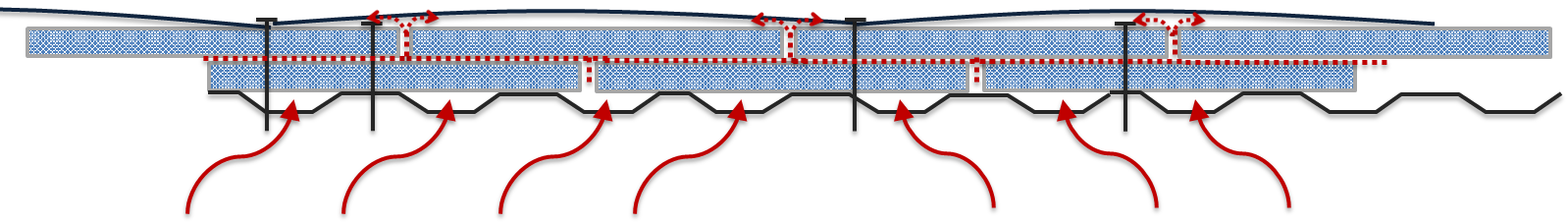

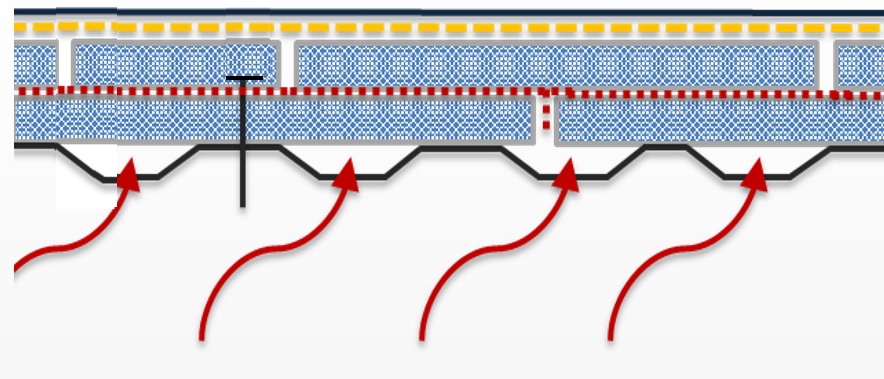

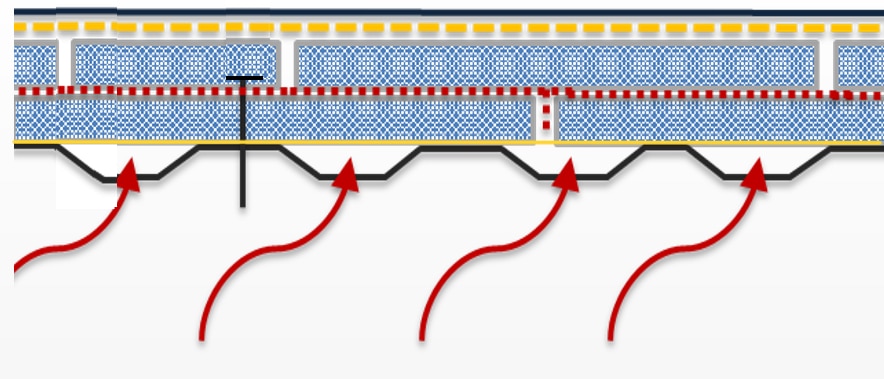

Roof assemblies vary in how much air gets into the assembly from the interior of the building (think stack effect or hot air rising through a space). This varies based on how the layers of an assembly are attached and if a vapor retarder is installed. As the red arrows illustrate in Figure 2 below, by using an adhered membrane instead of mechanically attaching it, air can't push up through the assembly and billow the membrane. And when a dedicated air barrier is added to the roof deck, air (and heat and moisture) can't get into the roof assembly at all. Adding an air barrier also minimizes the wind uplift pressures on the roof assembly.

Figure 2. Three different roof assemblies allowing different amounts of air and moisture.

Determining Whether a Vapor Retarder Is Needed

If a building has a dedicated air barrier, it may or may not need a vapor retarder. Vapor retarders—which aren't always a full barrier, so "retarder" is the correct term—slow the migration of vapor through the roof assembly, lower condensation risks, and function as an air barrier, if installed as such.

The International Building Code recognizes three classes of vapor retarders, ranging from Class I at or less than 0,1 perms to Class III at less than 10 perms. Materials with a permanence greater than 10 perms are classified as permeable and aren't recognized as retarders. The problem comes when designers want to install retarders in a location and in such a way that moisture can get inadvertently trapped between two materials with low vapor permeance.

The effects of this can be seen in the image below, where the roof assembly has degraded as a result of long-term trapped moisture.

Figure 3. Moisture trapped between two Class I vapor retarders caused degradation of the insulation and roof deck (Image courtesy of SGH).

The best option is to install the vapor retarder on the warm side of the insulation and use it as an air barrier to prevent moisture from getting trapped between materials.

Using Vapor Retarders as Temporary Roofs

When Class I vapor retarders are installed on a concrete roof deck or on top of a cover board over a metal roof deck, they can function as a temporary roof during construction. This allows interior finishing to start until the trades are ready to complete the roof.

The final layers of the roof assembly can be installed when no further construction will be done on the roof. This provides a clean, aesthetically pleasing roof, as was required in the casino project pictured below.

Vapor Retarders Benefit Roof Performance

Ultimately, air barriers are a code requirement for all new roofs based on the IECC. However, vapor retarders remain optional depending on the project's needs.

In cases where there's a concrete deck, a temporary roof is desired, or a high vapor load is on the interior of the building, vapor retarders and properly designed assemblies benefit roof performance by keeping air and vapor where they're meant to be.

Curious to learn more about the crucial role air barriers and vapor retarders play in roofing installation? Check out this vapor retarder overview video. You can also connect with trained experts at GAF by emailing us at buildingscience@gaf.com.