As a roofing contractor, safety and efficiency are your top priorities. While it may seem like a small detail, choosing the right ladder for the roof can mean the difference between a smooth, safe job and a frustrating, potentially dangerous one.

Ladders are a means to an end in the roofing business, but a single misstep can cause workplace injury, labor loss, unplanned healthcare costs, work delay, and more. Tragically, preventable falls are the leading cause of death in the construction industry. In 2022, falls from elevation caused 395 construction fatalities, according to the Bureau of Labor Statistics.

Here's an overview of the importance of ladder safety, the types of ladders you might use on the job, strategies for preventing falls, and tips for choosing the right roof ladder for each situation.

Safety Pays, Falls Cost

Statistically, smaller construction companies—that may try to save by not investing in new safety gear and training—typically bear the highest cost of falls. In fact, the Centers for Disease Control and Prevention (CDC) reports that approximately 70% of all fatal falls in the construction industry occurred to those working for employers with less than 10 employees. That's why knowing which ladder to use and implementing roof fall prevention measures are some of the best investments you can make.

Through thoughtful planning and careful training, you can help enhance the safety of your team while reducing unnecessary costs and injuries. In turn, this could potentially inspire employee loyalty and earn customer respect.

Types of Ladders for Roof Access

Depending on the roofing job, you may choose to use several different ladders. Here are the most common types that contractors use to gain roof access.

Extension Ladders

Extension ladders are portable and versatile, built for reaching higher points like roofs and gutters. They can provide access to sloped roofs and other harder-to-reach surfaces.

Safety tips: Current regulations state extension ladders must have all four rails supported (feet and end caps) on firm supports and maintain a 75 degree set-up angle during use to avoid ladder slide-out, according to the American Ladder Institute (ALI). The top three rungs of an extension ladder are not to be used for climbing. In addition, ALI advises that an extension ladder that extends more than three feet beyond the upper support point is too long, because it can act like a lever and cause the base of the ladder to move or slide out.

Stepladders

Sturdy and portable, stepladders are designed for lower elevation access such as low gutters or low slope roofs, as well as interior tasks like inspecting attics or ceilings.

Safety tips: Safe stepladder use requires firm, level support (no elevation or sinking) under all four feet. Do not stand on the top cap as it can lead to falls.

Telescoping Ladders

Telescoping ladders offer both height and portability, thanks to their collapsible design. With two points on the ground, they also offer some stability, but can't reach the heights of an extension ladder. Accordingly, they can be used to access lower heights and interior spaces.

Safety tips: Verify each section is safely locked into place before use. As with all ladders, always keep three points of contact (two hands, one foot, etc.) on the ladder.

Strategies for Using Ladders to Gain Roof Access

You can help spread the importance of ladder safety to your colleagues through campaigns like the 2025 National Safety Stand-Down. Additionally, you can keep work sites safer by posting roof safety infographics (available in English and Spanish) and encouraging the use of specialized apps.

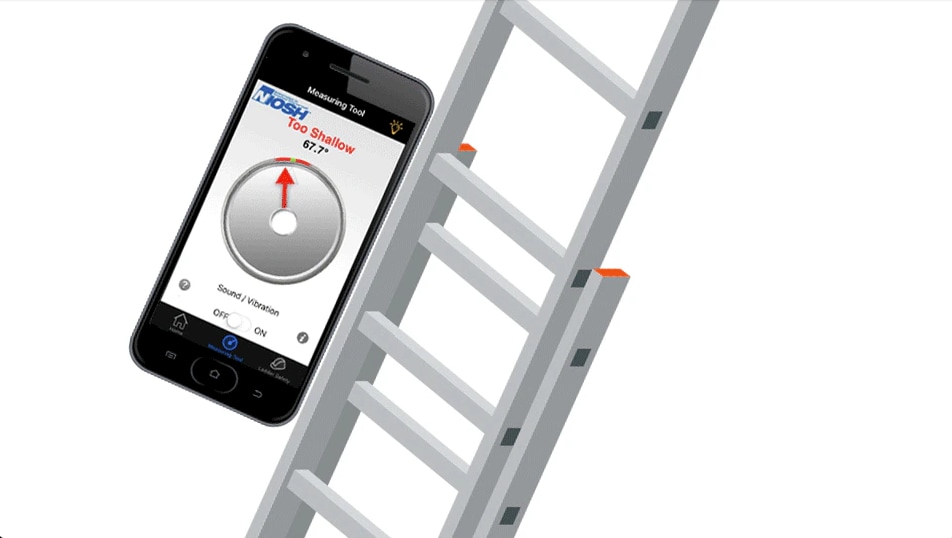

The National Institute for Occupational Health and Safety offers a free Ladder Safety app in English and Spanish. The app features a calculator that recommends proper ladder type and size (based on job, a workers' weight, and load), as well as an angle-measuring tool that uses visual, sound, and vibration cues to set an extension ladder at the proper angle.

The following strategies can help you ensure ladder safety and reduce the risk of injury on the job.

Ensure Proper Ladder Setup and Positioning

Always follow guidelines for proper use, such as using ladder levelers on uneven ground to prevent tipping. Secure all surroundings to avoid potential interference with the ladder that could create imbalance. Avoid positioning the ladder over busy pathways, driveways, and doorways (or ensure doors are locked or properly blocked off).

Plan in advance to account for environmental factors (wet ground, uneven terrain, etc.) or setup hazards, and utilize ladder accessories for slippery ground, irregular top support, and more.

Follow Weight Capacity and Load Limits

Always follow manufacturer's instructions and labels on the ladder. Never exceed the load rating, and don't forget to add the weight of all tools, materials, and equipment.

- For self-supporting portable ladders like stepladders and telescoping ladders, OSHA requires they be capable of supporting at least four times the maximum intended load, except that each extra-heavy-duty type 1A metal or plastic ladder shall sustain at least 3.3 times the maximum intended load.

- For non-self-supporting ladders like extension ladders, OSHA requires they be used at an angle so that the horizontal distance from the top support to the foot of the ladder is approximately one-quarter of the working length of the ladder.

Perform Regular Maintenance and Inspections

Routinely check the components of your ladders to confirm they're all in good working order. Like an engine needs oil, your ladders need regular lubrication, routine cleaning, and protection from elements to remain reliable and safe.

Additionally, ensure safety information labels are visible on the ladder impart—missing labels can lead to injury or death. To help others remember the importance of ladder maintenance, print a worksite checklist and inspect each ladder before each use.

Use Fall Protection Equipment

Fall protection is a requirement of OSHA standards. Where needed, contractors are required to provide gear such as personal fall arrest systems, guardrail systems, warning lines, and safety monitors as indicated. Accessories like ladder levelers, spiked ladder feet, and ladder hooks—that are used for securing a ladder over a roof's ridgeline—can also help improve job safety.

Factors to Consider When Buying a Roof Access Ladder

Roofing contractors may need multiple types of ladders for roofing jobs. Keep in mind your storage capacity, how portable you need ladders to be, and the most common type of roofing jobs you perform.

Height and Reach Requirements

A ladder's advertised height is the total length of the side rails, not the height that's safe to climb. The National Ladder Institute cautions that the advertised height doesn't account for reduced height due to set up angles.

Material and Durability

Aluminum is the most common ladder material thanks to its strength and light weight. Ladders may also come in wood, fiberglass, or reinforced plastic. Always plan for your job site's environment and the weather. For example, never use a metal (aluminum) ladder near exposed electrical elements or if there's a chance of lightning.

Ladder Safety Is the Law

Not only is roof fall protection a smart investment, it's the law. Year after year, across all industries, the top violation cited is substandard fall protection on construction sites. As a roofing leader, you can get involved to save lives.

Connect with a Safety Stand-Down regional coordinator to participate in a nearby event and earn a certificate of achievement. Encourage fellow workers to use tools like the Ladder Safety app. Post ladder safety posters—the CDC offers visual safety guides in English, Spanish, Polish, and Russian. Talk with your crew and learn how to help them be safe.

And always choose the right ladder for the roof to help ensure safety for your workers and yourself.

Contractor Resources from GAF

Are you ready to grow as a roofing contractor? Stay on top of the latest in roofing safety, best practices, and business strategies as a business owner by connecting with the GAF CARE Contractor Training team.

*Disclaimer: This is not certified training material, nor endorsed by training or certification bodies. Please refer to the Occupational Safety and Health Administration for all safety guidelines.