Concrete decks are one of the more common types of low-slope roof decks for commercial buildings. Steel and wood roof decks are the other most common types. Concrete roof decks make up approximately 13-14% of the new and retrofit low-slope construction market, according to the National Roofing Contractors Association (NRCA) 2015-2016 Market Survey. This article examines the advantages of concrete roof decks, the various types, and some of the precautions that should be taken to ensure success.

Advantages of Concrete Decks

While there are many advantages to concrete decks, there are two primary reasons to consider them. These are based on desired fire ratings and structural requirements.

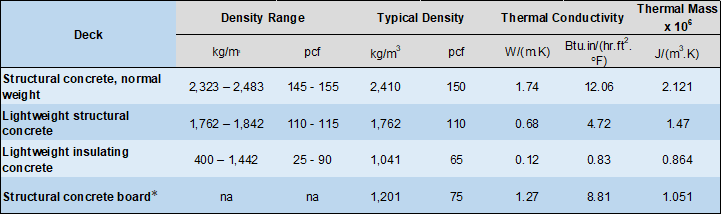

Concrete can have a wide range of densities depending on the type and amount of aggregate used, the amount of water used in the mixture, and whether air is introduced as a foam via the use of surfactants and the like. Concrete for roofing applications generally fits into one of several categories, depending on the requirements. The properties of each type cover a range depending on the raw materials. The following table shows density ranges followed by typical property values that can be expected.

* Values for the concrete structural board are estimates based on the published density.

Designers and specifiers should always note that actual property values will depend on aggregate type and source, the volume of water used, and other raw material factors. Always consult with local suppliers to ensure requirements are met.

When concrete is used as a structural component, designers typically specify the compressive strength. This is only loosely related to the compressive strength of the coarse aggregate and the American Concrete Institute (ACI) 213R-03 reports that for typical building-slab compressive strengths – up to about 5,000 psi – "there is no reliable correlation between aggregate strength and concrete strength."

There are five general types of concrete roof deck, as follows.

Structural Concrete Decks

These are cast-in-place and become an integral part of the structure. They use normal weight concrete and are designed to carry heavy loads. Foam insulation such as polyiso can be adhered on top, followed by the roof membrane. Also, the structural roof deck can be insulated with poured in-place lightweight insulating concrete with the roof membrane installed on top.

Structural Concrete Composite Deck

These are based on a steel panel deck system that is overlaid with normal weight or lightweight structural concrete. Loads are carried by the combination of the steel deck and concrete, which act as a single component. Typically, the steel panels are embossed to ensure mechanical coupling to the concrete. Like structural concrete roof decks, composite decks are normally insulated using adhered foam insulation panels or poured-in-place lightweight insulating concrete.

Lightweight Insulating Concrete Decks

Lightweight insulating concrete (LWIC) can be poured over a variety of structural deck systems that have been designed to carry loads. These can be either of the two structural concrete deck types already described or a structural steel deck. While published properties of LWIC are based on the use of lightweight aggregates or foamed concrete, LWIC can also incorporate foam boards. The following picture shows lightweight insulating concrete being poured over boards that have been set into a thin layer of LWIC.

When this is done, the concrete completely encapsulates the foam, which is frequently expanded polystyrene. The picture is of a Siplast system, and the resulting structure is shown here:

By arranging boards of different thicknesses, combined with smoothing of the surface, a positive pitch can be achieved to allow for good drainage.

Precast Concrete Decks

There are a number of types but usually, the precast members are comprised of reinforced, pre-stressed or post tensioned normal weight concrete. They can be T-shaped or hollow form planks. The precast assembly is normally covered with a layer of poured lightweight insulating or structural lightweight concrete, which serves as a leveling layer. Because the precast planks are usually covered with a poured concrete, they are considered as equivalent to poured structural decks for the purposes of this article. As with the previous types, the roof is completed with adhered foam insulation and a membrane.

Structural Concrete Boards

These are relatively thin (typically ¾ inch) factory formed boards that are screwed down onto a structural steel support (e.g., "C" channels). Conceptually, they can be thought of as being similar to steel deck panels that are installed over steel joists, but offering greater fire protection. Insulation can be mechanically attached or adhered, followed by application of the membrane.

Advantages of Poured Concrete Decks

Whether they are structural or insulating, poured-in-place concrete decks have a number of advantages.

Fire ratings: In accordance with ASTM E119, Standard Methods of Fire Tests of Building Construction and Materials, the American National Standards Institute (ANSI) and Underwriters Laboratories (UL) list minimum concrete thicknesses required for various fire ratings. The following table is summarized from ANSI/UL 263 Design No. J718.

As the density decreases so does the thermal conductivity and hence the fire rating is improved. However, as density decreases so does the compressive strength.

Wind uplift ratings: As wind rises up and over a building, it creates uplift pressure that exerts an upwards force on roof membranes. By greatly restricting air flow up into a roof assembly, the resistance to that upwards force is increased. Poured concrete decks can be effectively sealed at penetrations and roof edges and greatly reduce the amount of air that can penetrate upwards. This is shown in the following schematic comparing a poured concrete deck with a steel deck.

There are two main reasons why concrete decks can potentially improve wind uplift resistance, depending on concrete specification and overall roof assembly design. First, fasteners in structural concrete have a much higher pull-out strength compared to steel. With #14 fasteners for example, it's by a factor of over 2:1. Second, a steel deck system that has an adhered membrane and mechanically attached insulation can be ultimately limited by the fastener pull-out strength. This tends to limit the wind uplift resistance for roofs with steel decks to approximately 1-180 psf in 12x24 wind uplift testing. However, fully adhered structural concrete deck systems have achieved 1-300 psf or higher in similar testing.

Even though wind uplift resistance is often discussed in terms of wind speeds, the actual cause of roof wind uplift is slightly more complex. Roof damage caused by wind occurs when the air pressure below the roofing assembly is greater than the air pressure above the building's roof. As wind flows over the building, the pressure directly above the surface of the roof decreases. At the same time, internal air pressure increases due to air infiltration through openings, cracks, etc. The result is a net upward force on the roofing system. While concrete decks, when installed properly, can greatly reduce internal air flow into a roof assembly, if penetrations through a concrete deck are made later, these must be carefully sealed to prevent upwards air movement.

Air barrier: The International Energy Conservation Code (IECC) considers concrete in the following forms to be an effective air barrier, provided that all seams and joints are sealed.

Cement board having a thickness of not less than 1/2 inch (12 mm).

A Portland cement/sand parge, or gypsum plaster having a thickness of not less than 5/8 inch (16 mm).

Cast-in-place and precast concrete.

As noted previously, poured concrete decks effectively seal around penetrations. However, with any concrete deck, it's important to carefully consider the roof to wall termination and ensure that all gaps are closed up and sealed.

Thermal mass: Improvements in the energy efficiency of buildings are commonly achieved through increased thermal insulation. In fact, most model codes use thermal insulation as the only method of improving energy efficiency of building enclosures. However, there are many indications that thermal mass could also offer a means to both improve occupant comfort and lower energy use. Thermal mass affects the dynamic flow of heat into and out of buildings but has not received as much attention as thermal resistance for improving the energy efficiency of building enclosures. Concrete can add significant thermal mass to an assembly. That thermal mass could help to dampen interior temperature swings and thereby improve occupants' comfort. Also, it can dampen and delay heat fluxes caused by the sun, moving peak heat flux from the mid-day to later in the evening. This could help improve energy efficiency especially for buildings only occupied during daytime hours.

Ability to Add Slope: A slope can be added to a poured concrete deck during installation. This was discussed in the LWIC section earlier. By achieving a positive pitch with the concrete, it is possible to eliminate the need for tapered foam insulation while enabling drainage.

Disadvantages of Poured Concrete Decks

Weight: Roof designers need to consider the added weight introduced by concrete decks. It is important to understand the weight of locally sourced concrete versus simply relying on data from national handbooks. Always consult with a structural engineer. An advantage of structural concrete boards is that the added weight is lower than for poured concrete. However, concrete boards then require careful sealing at joints and penetrations to reduce air movement up into the assembly.

Water content: Roof decks that are cast-in-place contain a high level of water when poured. This is true for normal weight structural concrete and, importantly, the amount of water is greatly increased with the use of lightweight structural concrete. Normal weight structural concrete uses regular aggregates (i.e., hard rocks) with a low moisture absorption rate, while lightweight concrete uses shales and clays that are expanded with air to make them less dense but they have a higher moisture absorption rate.

On a job site, regardless of concrete type, additional water is often added to the mix to reduce the viscosity to ensure concrete easily flows so there are no gaps or voids in the final product. Aggregate for lightweight concrete is often intentionally loaded with water because of the voids. This is necessary so the water needed for concrete curing is not pulled into the aggregate.

Typically the roofing industry has required a 28‐day curing period prior to testing the roof deck for "dryness" and suitability for roofing. This recommendation was garnered from the concrete industry's recommendation for the appropriate amount of time for concrete to cure and develop adequate compressive strength; however, the 28-day time frame is not related to the amount of water in the concrete, only to the cure time. The roofing industry now understands that concrete continues to cure and release excess moisture (i.e., dry out) for a significant time. It's important to note that lightweight concrete's higher moisture content (relative to normal weight) means a much longer drying time is needed.

When a concrete deck is poured, some of the mix water is used up by the curing process, and some evaporates; but the rate of evaporation is slow, so large quantities of water remain stored within the structure of the concrete for extended periods of time. Moisture retention is exacerbated by construction methods that install concrete over non‐removable non-vented metal forms (or other impermeable substrates). While the concrete itself is generally not damaged by this moisture, the moisture typically migrates into the roofing system where it is absorbed by materials that are more sensitive to moisture.

There are several technical advisories that have been issued to raise awareness about the potential for moisture issues associated with concrete roof decks. These include the National Roofing Contractors Association, the Asphalt Roofing Manufacturers Association, the Single-Ply Roofing Institute, the Polyisocyanurate Insulation Manufacturers Association, and the International Institute of Building Enclosure Consultants.

Allowing concrete to thoroughly dry is most appropriate; however, it is reasonably impractical to go beyond 28 days. So more realistic ideas must be implemented to accommodate a potentially substrate; those follow.

Installation of a vapor retarder on the top surface of the concrete deck. The Midwest Roofing Contractors Association (MRCA) advises that a vapor retarder of less than 0.01 perm is necessary over new concrete roof decks. From a practical standpoint, a vapor retarder of less than 0.01 perm is effectively a vapor barrier—almost no moisture passes through into the roof assembly. For more on the use of vapor retarders see this guide.

There are three classes of vapor retarders/barriers: Class I, II, and III. Each has a varying permeability rating. A Class I vapor retarder has a perm rating of 0.01 to 0.1; a Class II vapor retarder has a perm rating of 0.1 to 1.0; and a Class III vapor retarder has a perm rating of 1 to 10. MRCA is advising to use a better-than-Class 1 vapor retarder over new concrete roof decks because of its ability to prevent moisture from entering the roof system.

Although industry guidance points towards the use of a vapor retarder over concrete decks, designers must consider the potential issues with installing a roofing system with a double vapor barrier. Moisture that gets in between the roof membrane and the vapor retarder at the roof deck is essentially trapped.

Use a venting base sheet in conjunction with vents and venting edge details (at edges, parapets and penetrations) to provide a pathway to allow the moisture in a wet concrete deck to escape slowly over time.

Lightweight concrete should always be installed over a vented steel deck to allow downward drying.

For more information about moisture in concrete decks see this article by Kirby.

Advantages and Disadvantages of Structural Concrete Boards

Structural concrete boards improve the fire resistance of roof assemblies but, due to their relatively low thickness, do not offer the same fire resistance as poured concrete decks.

Concrete boards are factory cured and therefore do not have the moisture issues associated with poured concrete decks.

Concrete boards are similar to steel roof deck panels in that they do not prevent air and moisture from migrating up into the roof assembly. The following schematic shows that such systems can be "enhanced" by sealing around penetrations and applying a self-adhering vapor retarder to the concrete board deck.

Adhering the vapor retarder directly to the concrete deck ensures that it is below the dew point so long as a code-required level of insulation is installed above the vapor retarder. A good example of such a product is GAF's SA Vapor Retarder. For most vapor retarders, application direct to a steel deck doesn't meet many fire codes. Concrete boards can provide a good substrate for the application of the vapor retarder while also improving fire performance.

Conclusions

Concrete decks have a number of advantages over steel decks. These include improved fire ratings and wind uplift ratings. Also, concrete is classified by the IECC as an air barrier provided that seams and joints are sealed.

Care must be taken to ensure that moisture in poured concrete decks is prevented from moving upwards into the roof assembly. This is typically achieved by the installation of a vapor retarder over the deck.

Structural concrete panels are factory cured and can be a good substrate for self-adhered vapor retarders when there is a risk of moisture migration from within the building up into the roof assembly.